Qiddiya: the future largest entertainment centre in the world

Qiddiyah project is an entertainment megaproject that will be located 40 km away from Riyadh’s city center. The project is one of the tourism megaprojects to be established in Saudi Arabia in the framework of the Saudi Vision 2030 which aims to diversify the income resources of the country.

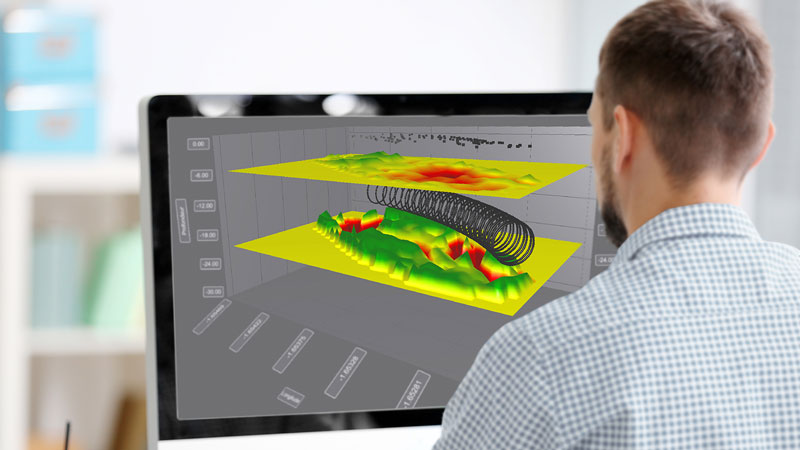

The Qiddiya project aims at being totally integrated within the existing landscape of the area, meaning that besides rock mass stability matters, all these future astounding structures will be subjected to severe wind loads, both uplift, overturning moments, and shearing, that will require deep foundations to resist the large lateral and vertical pull-out loads and special foundations to spread out the loads to prevent forces from inducing tension into the fractured rock system on the cliffs.

The challenging ground conditions therefore call for an extensive campaign of field explorations and state-of-the-art in-situ large scale pile and drilled pier load tests, laboratory testing, data analysis and evaluation, that will ultimately develop rock properties data to be used in designing foundations on the cliffs.

An extensive load test campaign

In the context of this project, Sixense was the subcontractor in charge of the instrumentation of bored piles, micropiles and anchors and the subsequent monitoring activities during the pull-out and lateral loading tests that were carried out by Keller.

7 drilled piers, 24 micropiles and 4 anchors were instrumented, 15 lateral load tests and 23 tensile tests were carried out. More than 500 strain gauges were installed and datalogged, along with load cells. ShapeArrays were used to determine the deflection of piles and micropiles during lateral load tests.

The monitoring data obtained was then compiled in factual reports, and provided to Keller. Soft copy spreadsheets were also provided to allow further processing/interpretation of the data.

Types of instrumented structures

Load tests performed

Datalogged strain gauges

Dedicated testing teams