Client:

Etihad Railway, Zetas

Etihad Railway, Zetas link opens in a new tab

Railway and bridge infrastructures for a local strategic link

The Etihad Rail network, a key element of the pan-Gulf railway network, is a major project that aims to link key industrial centers with more urban, suburban and remote communities and neighbourhoods. Behind the project is a hope for boosting trades as well as the industrial development of the region in order to support the long-term growth of the national economy.

Etihad Rail network is being developed and implemented in two main stages:

- Stage 1 links the Shah Sour and Habshan gas fields to the port of Ruwais

- Stage 2 will extend from the Saudi border at Ghuweifat to Fujairah.

The network will cross the Emirates via Abu Dhabi, Khalifa Industrial zone, Khalifa Port, Jebel Ali Port, Dubai, Sharjah, Ras al-Khaimah and Fujairah on the East Coast, linking with the existing stage 1 line at Ruwais, and effectively uniting the major industrial ports and trading centres of the country.

A challenging project environment

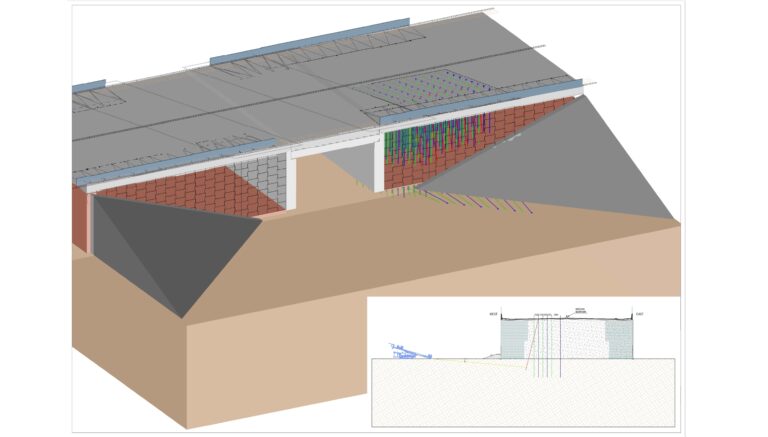

The Bridge 0BR09, included in the Etihad Railway development, is an over bridge (road-over-rail) located at Al Mirfa, between Ruwais and Abu Dhabi. The bridge substructure comprises in-situ RC stem on pilecap, supported by a large pile group due to complex geological formations underneath. Mechanically stabilised earth walls have been used as access ramps to the bridge. Due to dissolution of gypsum layers within foundation soil, localized subsidence was triggered below reinforced soil and specialist Zetas was called upon to perform compensation grouting to strengthen the ground with a series of inclined multiple Port Sleeved Pipes, or TaM (Tubes a Manchettes), and other grouting operations.

Sixense monitoring expertise applied to a key element of the project

Sixense expertise was required on the Bridge 0BR09 to provide an adapted monitoring service. In addition to the instrumentation of the bridge with one automatic total station and 40 optical prisms, Sixense also provided a baseline and automatically monitored, in real-time, the 3D movements of the bridge and the structure as a whole. Sixense presence was requested not only during the injection phase but also afterwards to ensure the Etihad Rail Bridge full stability and safety.

Automatic Total Station

optical prisms