Client:

During and after construction

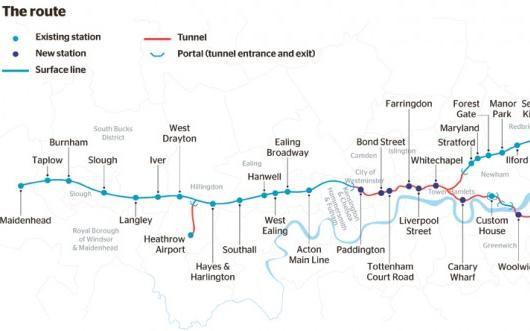

Eight tunnel boring machines have weaved their way under the existing infrastructure of Central London removing 4.5 million tonnes of earth along the alignment. 42 km of tunnels, 10 completely new stations and 30 upgraded stations make up the biggest construction project undertaken in UK. The dense urban environment associated with a major capital city has meant that the entire route has a requirement for comprehensive movement monitoring, before, during and, because of the regional geology, after construction has taken place.

Crossrail decided to provide an umbrella monitoring system that would allow, protection of existing assets and compliance with 3rd party regulatory requirements such as Network Rail, London Underground, Docklands Light Railway and various utility providers and property owners. This system would also provide supplemental information to the many contractors working simultaneously on Crossrail who are expected to undertake their own construction related monitoring to protect their site and neighbours.

A partnership

The movement monitoring system consists of a wealth of automatic structural and geotechnical sensors as well as 215+ automatic total stations (ATS), working in groups along the alignment.

Sixense, have maintained, managed and repaired this overseeing monitoring system. To deliver a robust, reliable and accurate monitoring system a number of crucial strategies have been implemented:

- working in partnership with Crossrail to ensure their requirements are reflected in the ongoing management and maintenance programme for the existing instrumentation infrastructure

- implementation of an automated KPI tool, studying the system parameters/trends, allowing real time diagnosis of instrument performance.

- a proactive strategy of maintenance is then implemented prioritising and redirecting resources when necessary

- upgrading of the monitoring system by using Geoscope software

Robotic Total Stations

Prisms

Tilt sensors

Electrolevel Beams

Coverage